Planning of a MY24 Midsize Pickup

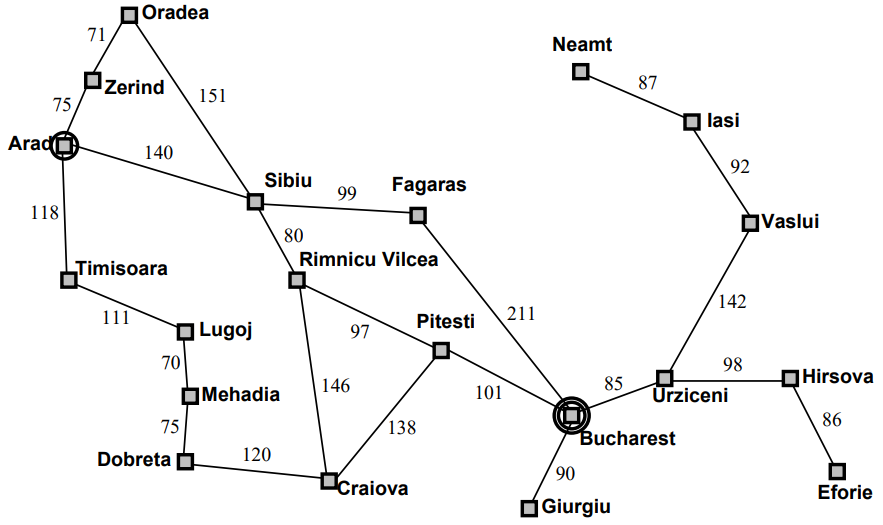

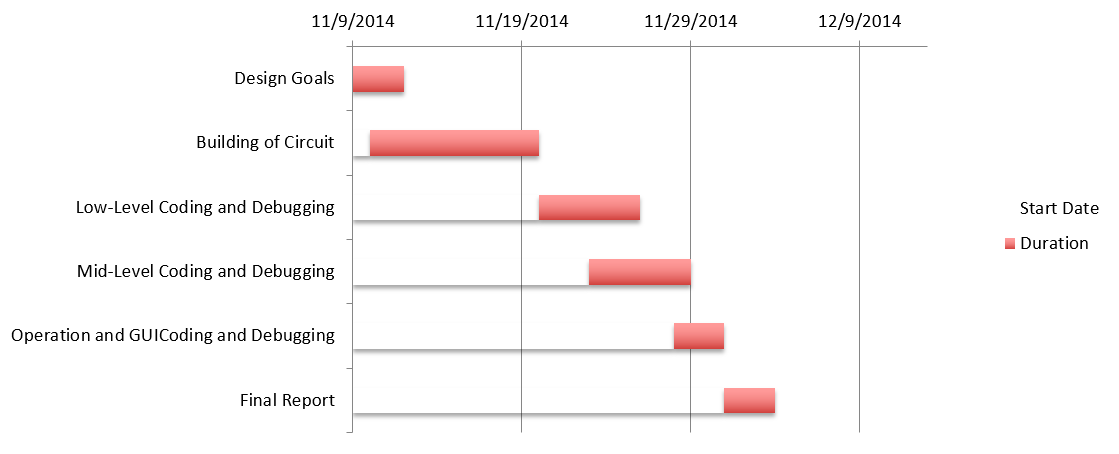

In this project a team of of five including myself planned out a MY24 Honda Ridgeline. Starting out we looked at the current mid-sized truck market. Aspects such as what vehicle are in this segment, who the customers are, and what the customer needs are. We then compared the various mid-size trucks, looking at multiple aspects and creating side by side comparisons. To better analyze these vehicle we created pugh diagrams comparing customers needs, vehicle attributes, and vehicle systems. We also looked at future regulatory requirements that would be needs for a MY24 vehicle.

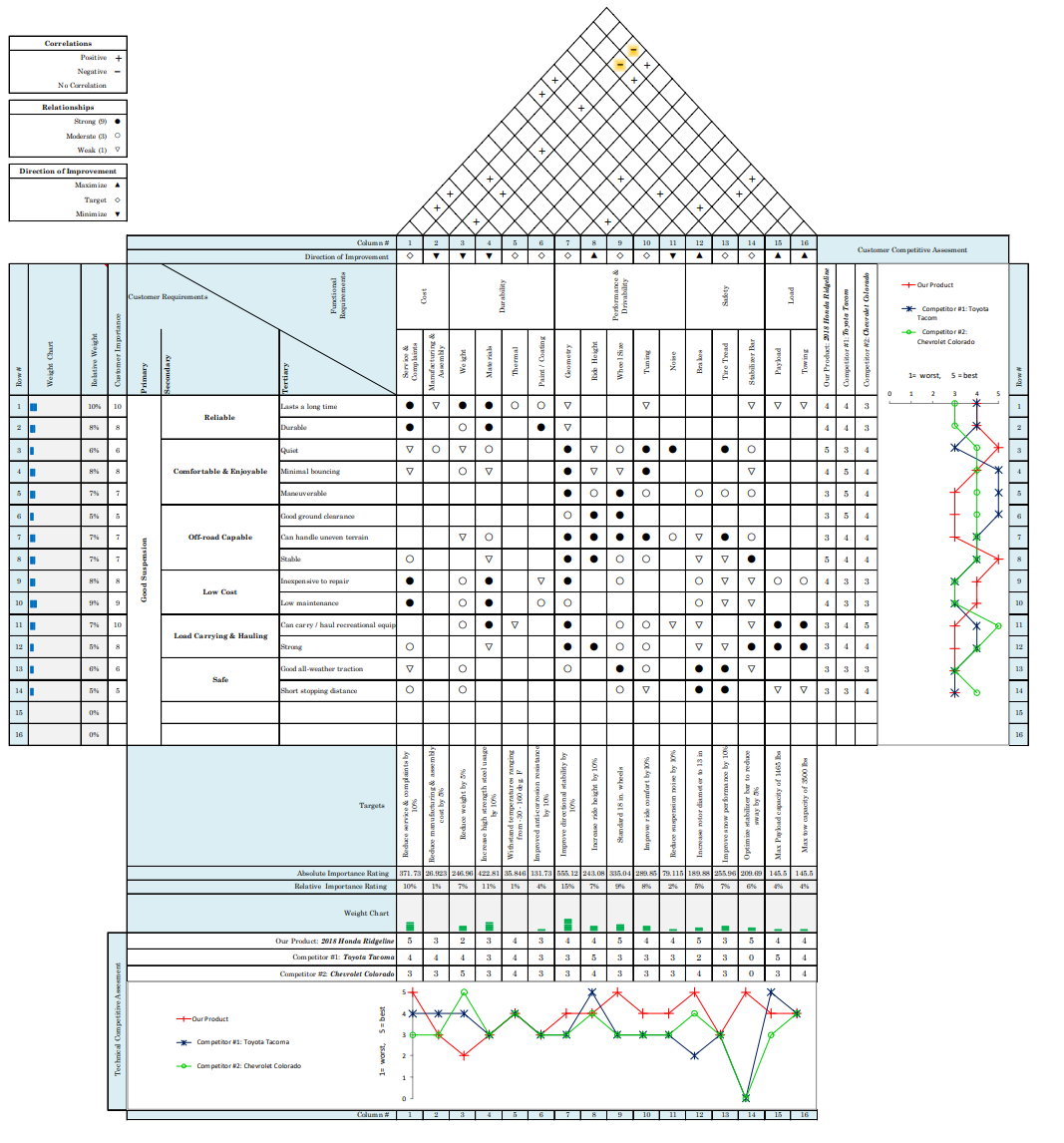

Quality Function Deployment

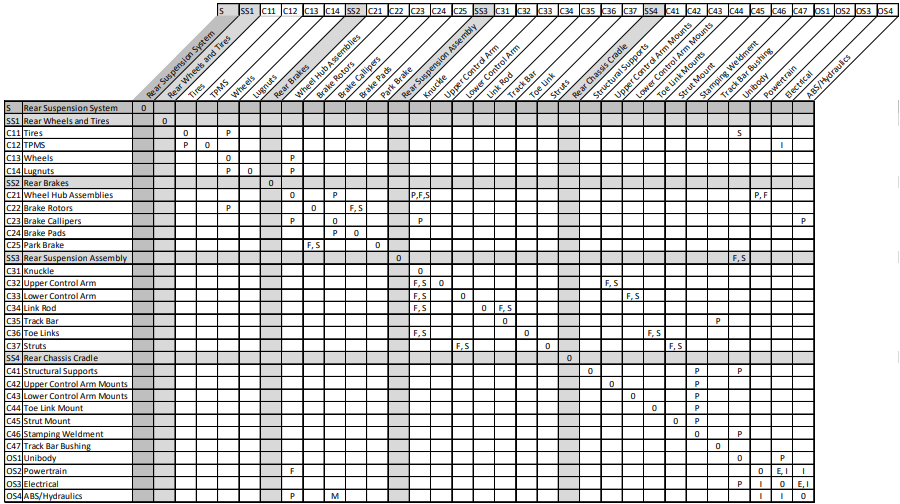

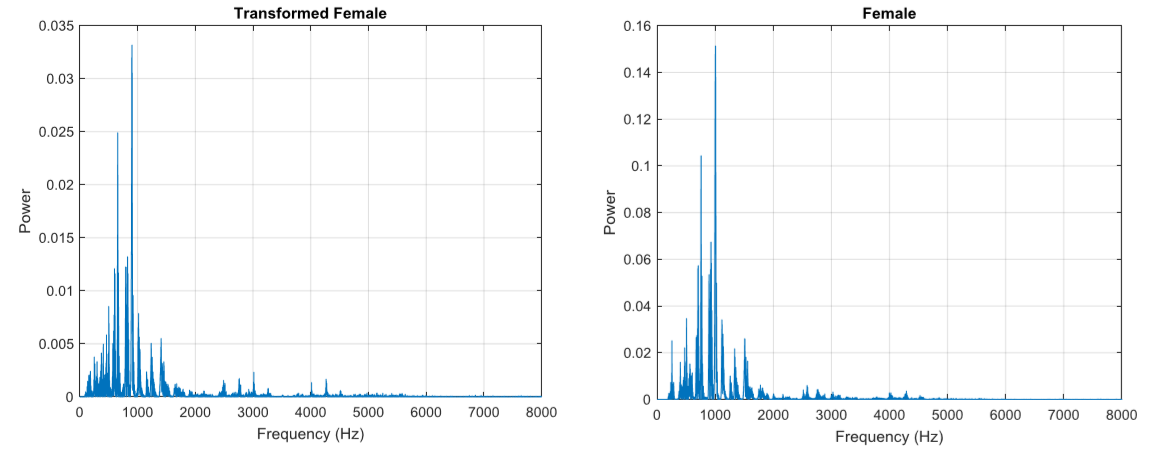

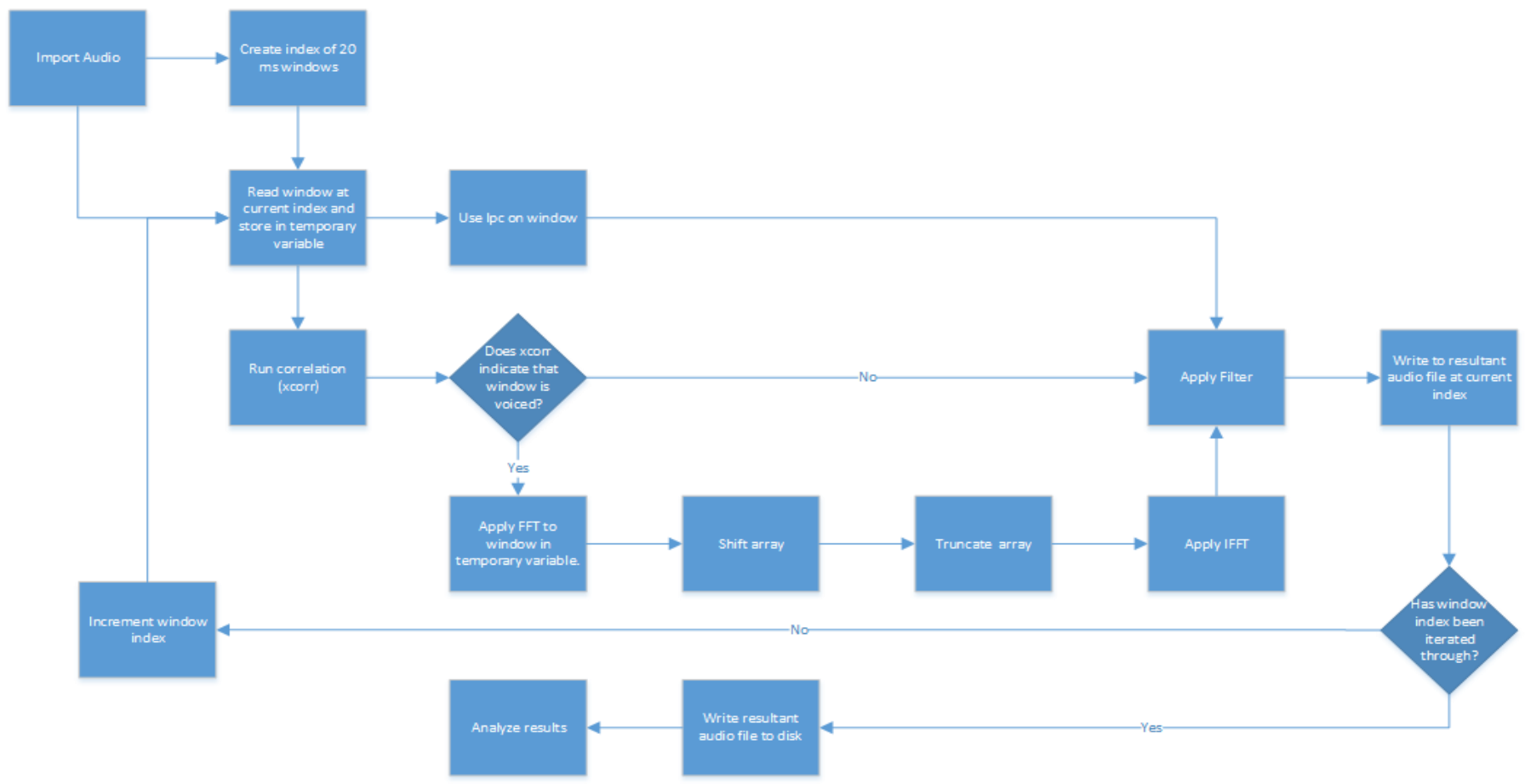

Next we cascaded requirements for our vehicle and looked at how our suspension system integrates together. To create our requirements and see their importance we created a quality function deployment (QFD) diagram to go from customer requirements to functional requirements. Next we looked at our selected vehicle system, the rear suspensions system. We were able to take our vehicle attributes and requirements and cascade them into systems and subsystem requirements. Finally we created and interface matrix and diagram to better organize how teams should communicate to make a cohesive system.

Interface Matrix

Finally we got into more specific planning with business plan, a conceptual design, and technology plan. Here with business plan we had to put in more detail projections details such as program timing, who would buy the vehicle, and how the vehicle is good financially. With the conceptual design and technology plan we outlined our dimensions and features for the MY24 Ridgeline. We also looked at technology challenges and risks with each new feature in our technology plan.

Reports: